WASA HERMETIC

Polyurethane-coated steel support

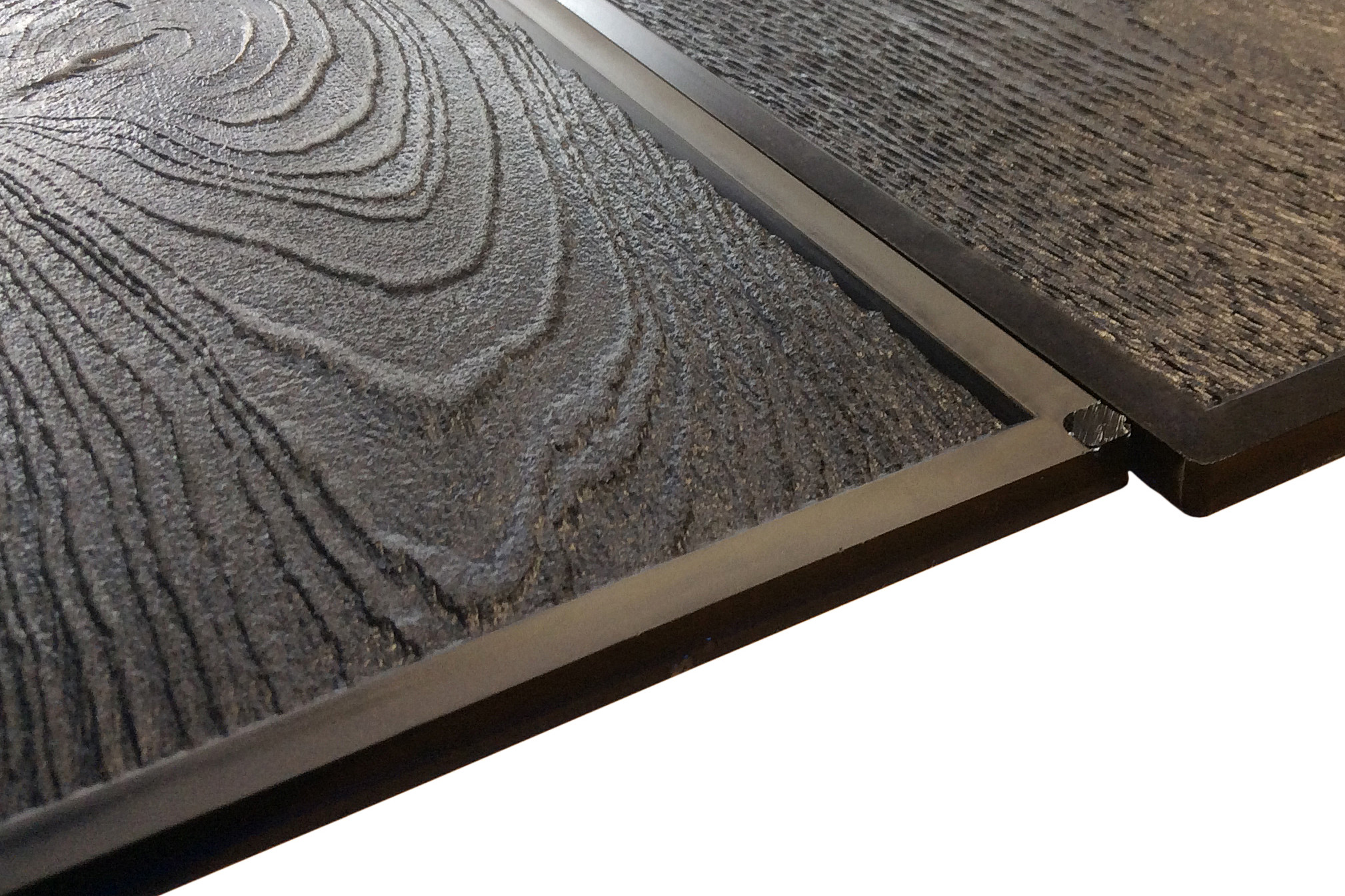

Short cycle times and highly compressed concrete block products: These are just two of the many advantages of the production process on hydraulic presses. Now widespread, the range includes fine-grained exposed aggregate concrete products and smooth slabs with ground or fine-blasted surfaces. In the hydraulic pressing process, a relatively liquid concrete layer is pressed together with an earth-moist substrate. The properties of the first concrete layer and thus the later stone surface make them suitable for reproducing the finest textures, in a similar way to a wetcast concrete.

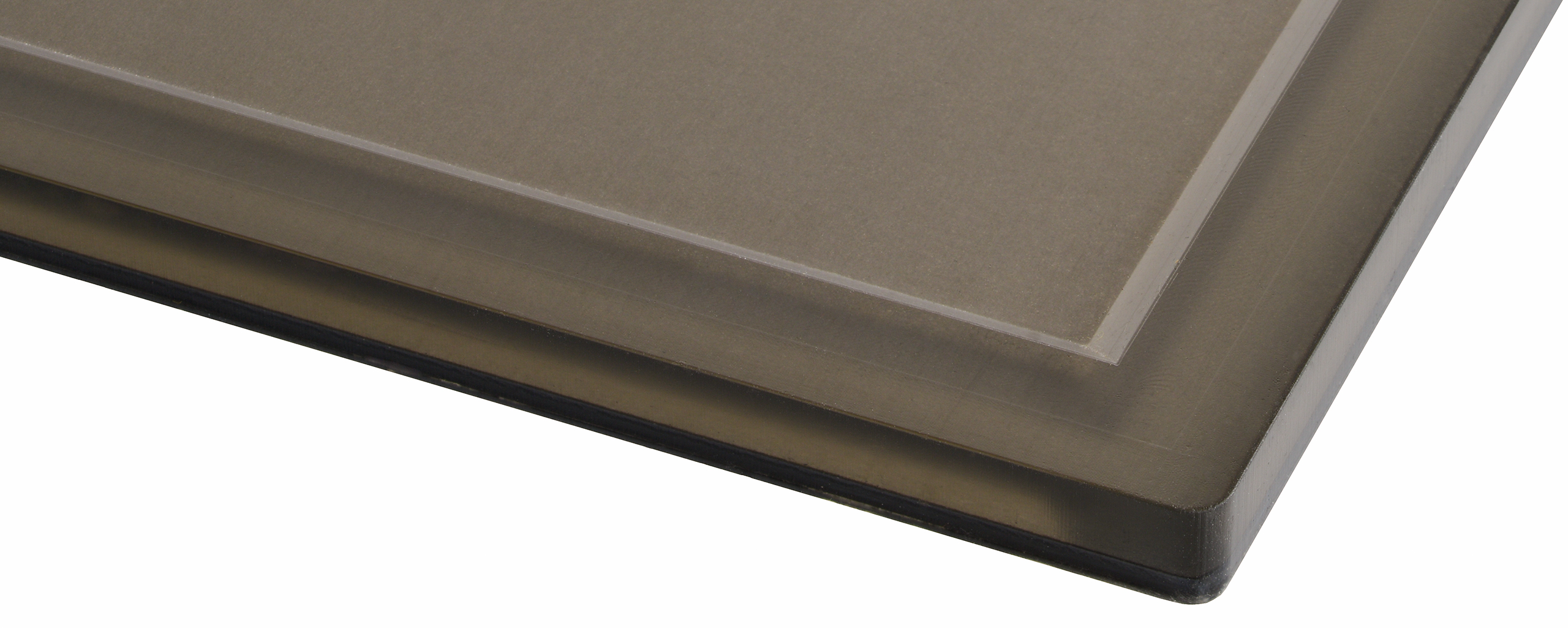

This is where WASA HERMETIC with its highly wear-resistant polyurethane liners comes in. The liners are produced from a two-component casting resin in Shore A70 developed especially for this application. Moreover, because a two-millimeter-thick steel sheet on the back of the liner ensures very high dimensional stability, the polyurethane liners can be placed in any hermetic rotating table press. Further advantages of WASA HERMETIC:

Advantages

Detailed reproduction of abstract and natural surfaces, resulting from a closed, not open-pored polyurethane layer

Reduced adhesive forces on the liner surface

Improved demolding thanks to active recovery of the PUR systems used

Stronger, more vibrant colors thanks to closed concrete surfaces

Unlimited options for design, size and feel

Option of producing large-format concrete slabs

The concrete block products produced with WASA HERMETIC have already been added to the portfolios of manufacturers across Europe and are supplied to both garden and landscape construction companies and specialist retailers. WASA does not charge a license fee for the design. However, the trend is moving towards individual architecture projects. WASA works closely with the concrete processor and their product development department here. HERMETIC plants are used to develop concrete slabs in large quantities and up to liner dimensions of 1021 x 1021 mm. Steps, facade elements, design elements, and flower bed and pool edging in the same design and feel are ideal when added to or combined with the products. These concrete products can then be produced with WASA WETCAST. For customer-related projects, WASA guarantees customer protection for the concrete processor.

WASA offers modular design flexibility by fusing WASA WETCAST molds with WASA HERMETIC liners. Concrete processors can implement individual, holistic projects through symbiosis of the two production processes. When it comes to project consulting, WASA draws on comprehensive experience in mold and tool construction, discussing the most economical solution and application with the customer.

YES, I WOULD LIKE MORE INFORMATION!

Please give me more information on the following WASA CONSTRUCT products and services (multiple selection possible). This is a non-binding inquiry, not an order.