WASA WETCAST PRODUCTS

WASA WETCAST MOULDS

Our professional craftsmen design and produce complex and custom-made models as well as simple and fancy ones. In accordance with customers’ project requirements, we use these models as master for making high-quality single and multiple polyurethane and silicone moulds. WASA WETCAST supporting frames ensure the stability and durability of moulds during production.

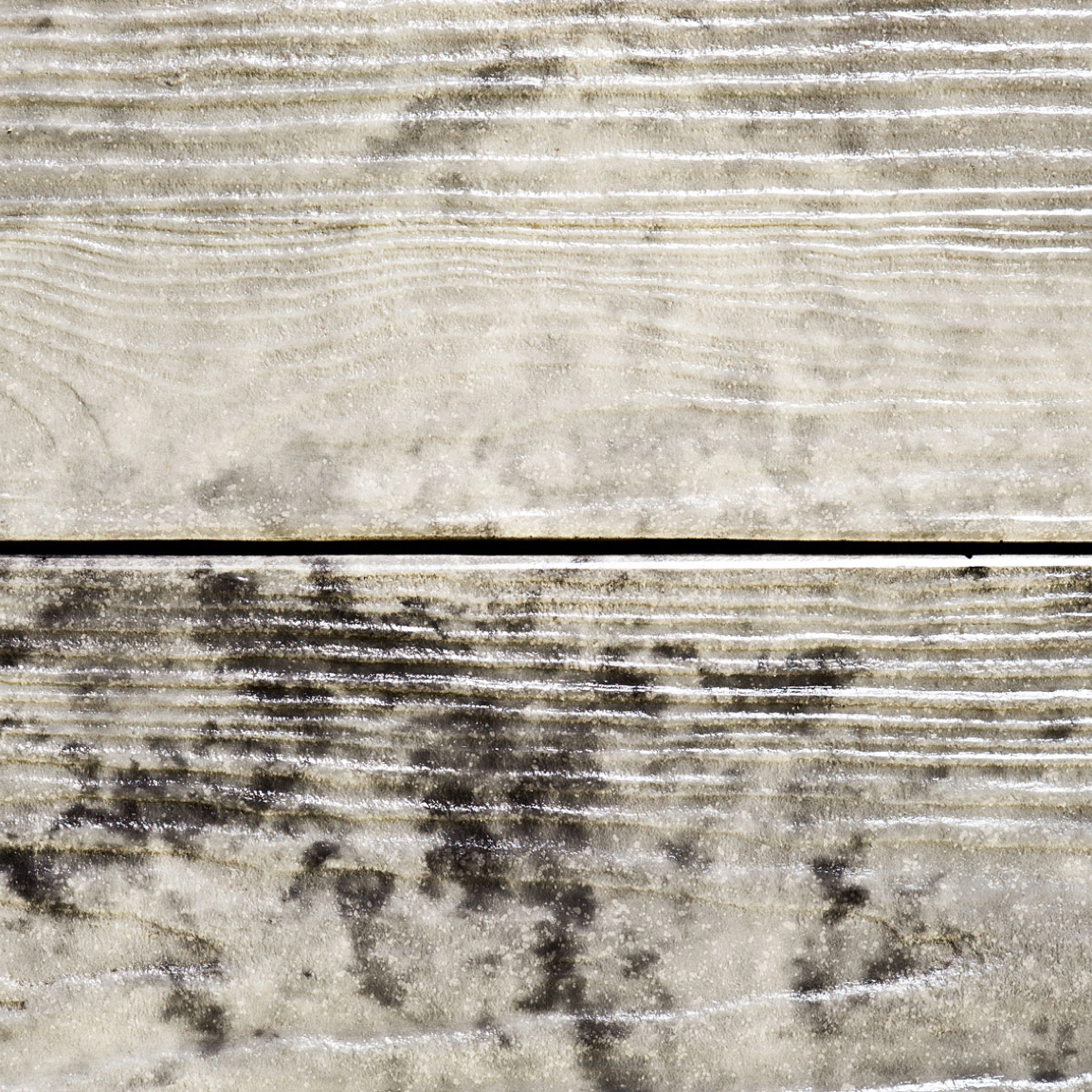

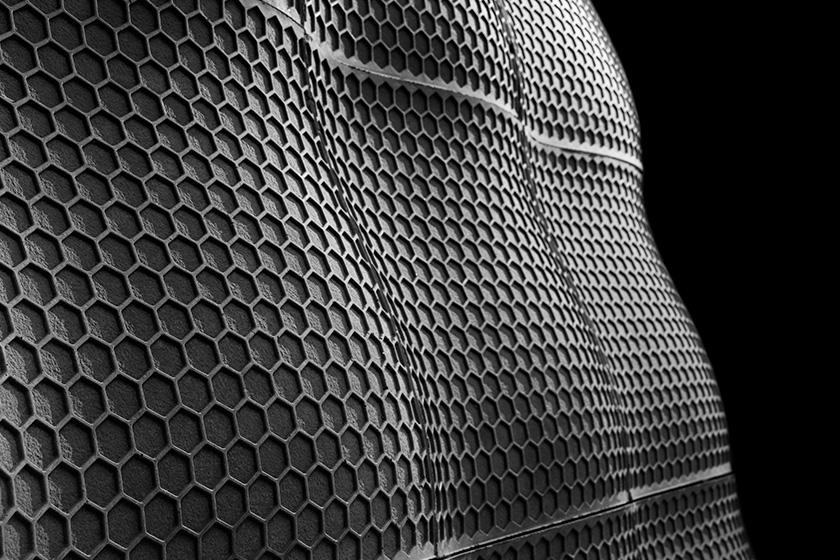

Concrete blocks

Natural stone, wood or other surfaces easily replicated with WASA WETCAST moulds. You get gorgeous concrete products and always true to the original.

WASAWETCAST mould

We use 100% colour-neutral and mercury-free polyurethane for the production of our top quality moulds. A special casting machine, developed by WASA itself, ensures mould making without air pockets.

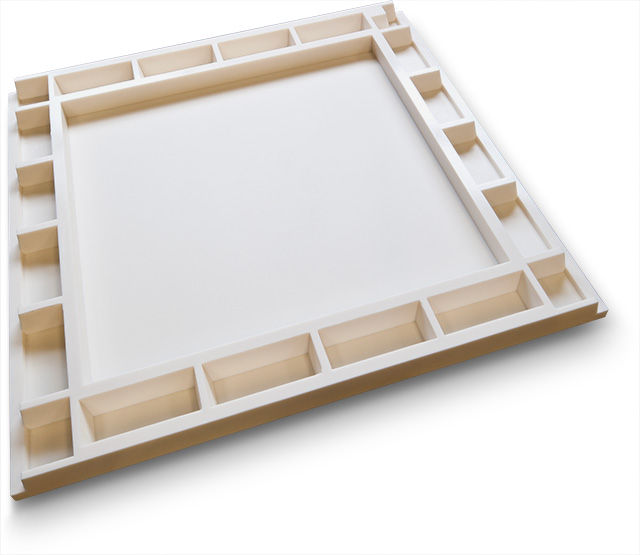

WASAWETCAST supporting frame

For our WASA WETCAST supporting frames we use high-quality wood from Europe. The moulds get even more stability when filled with concrete. Our portfolio includes also steel frames with attachment parts and powder coating.

Individual moulds & structures

Dimensional accuracy

Optimal demoulding

No colour residues on concrete product

Tear-resistant

Special moulds

We also manufacture special moulds for design and assembly concrete elements. Get in contact with us for more details.

REFERENCES

WASA WETCAST moulds for a precise reproduction of modern and traditional, fancy and original surfaces. The results are stylish and most adorable concrete products.

Below you will find a selection of successful customer projects achieved with WASA WETCAST moulds.

PRESBETON Nova, s.r.o. - Czech Republic, Olomouc

PRESBETON Nova, s.r.o. - Czech Republic, Olomouc

PRESBETON Nova, s.r.o. - Czech Republic, Olomouc

PRESBETON Nova, s.r.o. - Czech Republic, Olomouc

PRESBETON Nova, s.r.o. - Czech Republic, Olomouc

PRESBETON Nova, s.r.o. - Czech Republic, Olomouc

PRESBETON Nova, s.r.o. - Czech Republic, Olomouc

Greystone Ambient & Style GmbH & Co. KG - Germany, Eggesin

Greystone Ambient & Style GmbH & Co. KG - Germany, Eggesin

Greystone Ambient & Style GmbH & Co. KG - Germany, Eggesin

Greystone Ambient & Style GmbH & Co. KG - Germany, Eggesin

Greystone Ambient & Style GmbH & Co. KG - Germany, Eggesin

Greystone Ambient & Style GmbH & Co. KG - Germany, Eggesin

Greystone Ambient & Style GmbH & Co. KG - Germany, Eggesin

ABW Beton - Slowakia, Senec

ABW Beton - Slowakia, Senec

ABW Beton - Slowakia, Senec

ABW Beton - Slowakia, Senec

ABW Beton - Slowakia, Senec

ABW Beton - Slowakia, Senec

ABW Beton - Slowakia, Senec

Max Lochboden - Austria, Haidershofen

Max Lochboden - Austria, Haidershofen

Max Lochboden - Austria, Haidershofen

Max Lochboden - Austria, Haidershofen

Max Lochboden - Austria, Haidershofen

Max Lochboden - Austria, Haidershofen

YES, I WOULD LIKE MORE INFORMATION!

Please give me more information on the following WASA CONSTRUCT products and services (multiple selection possible). This is a non-binding inquiry, not an order.

PARTNERS

Requirements are changing ever faster in the concrete industry, too. WASA works together with strong, renowned partners to meet these demands. Our partners are among the world’s leading manufacturers of polyurethane systems for the concrete industry, releasing agents and admixtures, concrete substances and cement solutions.